Ecology vs. Greenwashing

Ecology and the effort to reduce our own ecological footprint increase the pressure to use the most environmentally friendly solutions for our nature. Plastic is often labeled as one of the main enemies. But does this material deserve its negative reputation? In many ways, it has improved our lives, and it’s hard to imagine life without it anymore. However, with new possibilities comes responsibility. Here lies the main issue: our behavior toward this material and waste in general. The production of any material places a burden on the environment, and comparisons are very difficult because, for example, the energy mix at the production site varies. In the case of packaging materials, it’s also necessary to consider the entire life cycle of the material, taking into account additional factors such as logistics or the packaged product and its own ecological footprint.

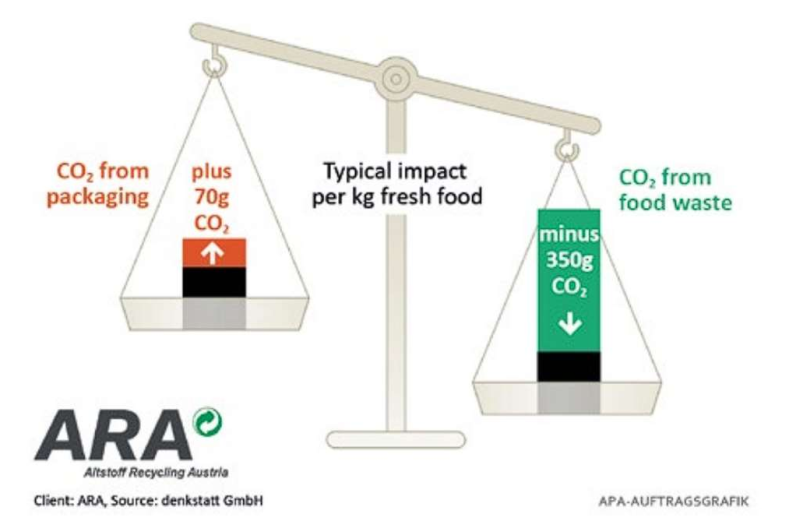

A great example and frequent target of critics is the plastic wrap on a salad cucumber. A simple, single-material packaging with minimal material use, which anyone can properly sort, keeps the cucumber fresh and marketable for up to 14 days longer, preventing waste of a valuable crop. The ecological impact of its cultivation is thus not wasted, yet it often becomes a target of criticism. According to the STOP Waste – SAVE Food project, the carbon footprint of discarded food is up to five times higher than the carbon footprint of its plastic packaging.

For the average consumer, the most visible battle has likely been between shopping bags in stores, where there was a major shift from “dirty” plastics to “eco-friendly” paper and various bio and degradable materials. Fortunately, the search for environmentally friendly solutions hasn’t stopped, and it’s becoming clear that the right path isn’t always straightforward, and the seemingly “eco-friendly” option isn’t always the better solution. Shopping bags demonstrate that this issue must be viewed through the lens of the product’s entire life cycle—from material production, through transportation and reusability, to its final disposal.

The production of a paper bag is up to four times more energy-intensive and involves the use of large amounts of chemicals. Producing 1 kg of paper also consumes approximately 321 liters of water, while the same amount of plastic requires only 13.7 liters. Additionally, the logistics of paper bags, due to their larger volume and weight, place a greater burden on the environment. pro přírodu

Deforestation is also a major topic, regardless of the fact that spruce monocultures are far from healthy forests, as demonstrated in recent years by, for example, the bark beetle calamity.

The bark beetle calamity, which has particularly affected the Czech Republic since 2015, is indirectly but significantly linked to the paper industry. Spruce monocultures, supported by long-term demand for wood in paper production, have proven vulnerable to climate change and pests such as the spruce bark beetle.

Comparison

Over time, this trend has also impacted the area of package fillers. Here, too, there is growing pressure to reduce the use of plastics. Unfortunately, this is often based on incomplete information and without a broader understanding of all the factors necessary for making a rational choice of suitable material.

Filling systems are packaging with a specific purpose: filling empty space and protecting the product. Air cushions made of PE film, which are inflated using a compact device at the point of use, face "eco-friendly" competition in the form of crumpled paper. In addition to the previously mentioned drawbacks—such as energy intensity, water consumption, water pollution, and the overall environmental impact of deforestation—paper has another disadvantage for this specific application: it cannot be inflated.

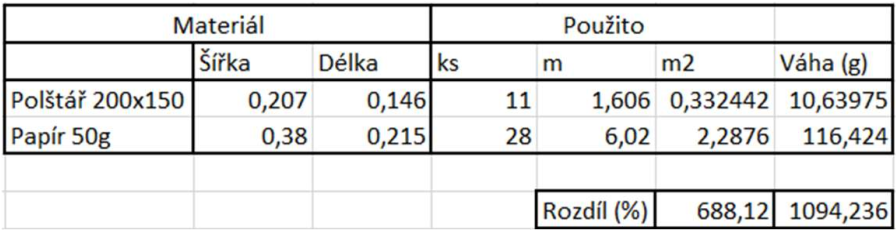

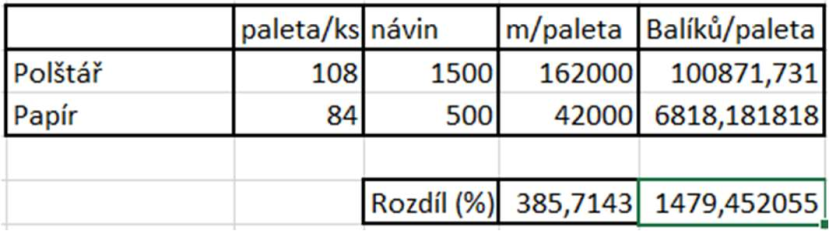

This property of air cushions is their greatest advantage. For example, consider a test involving the filling of a box (approximately 10 liters) with crumpled paper versus air cushions (note: the 200×150 mm size was deliberately chosen as the most universal, even though a 200×200 mm cushion would perform significantly better in the comparison).

The test showed that filling the same space requires up to 7 times more paper than air cushions, with the weight difference being nearly 11 times greater!

Moreover, when considering the more efficient distribution due to the smaller volume, one pallet of air cushions can replace up to 15 pallets of crumpled paper—equivalent to nearly half a truck!

This significant difference clearly demonstrates the advantages of air cushions. Their use not only saves a large amount of material, resources, and the overall environmental impact of production but also reduces fuel consumption for transportation. By using air cushions, we also automatically generate far less waste. If the recipient is an end customer who cannot reuse the filling, nothing is simpler than puncturing the cushion and disposing of it in the widely available yellow plastic recycling bin.

All this additional handling, such as waste collection, naturally further increases the carbon footprint.

We often encounter the opinion that transporting air is not eco-friendly. However, this reflects a complete misunderstanding of the issue, a lack of knowledge about packaging processes, and the complexities associated with packing a large number of packages with various products.

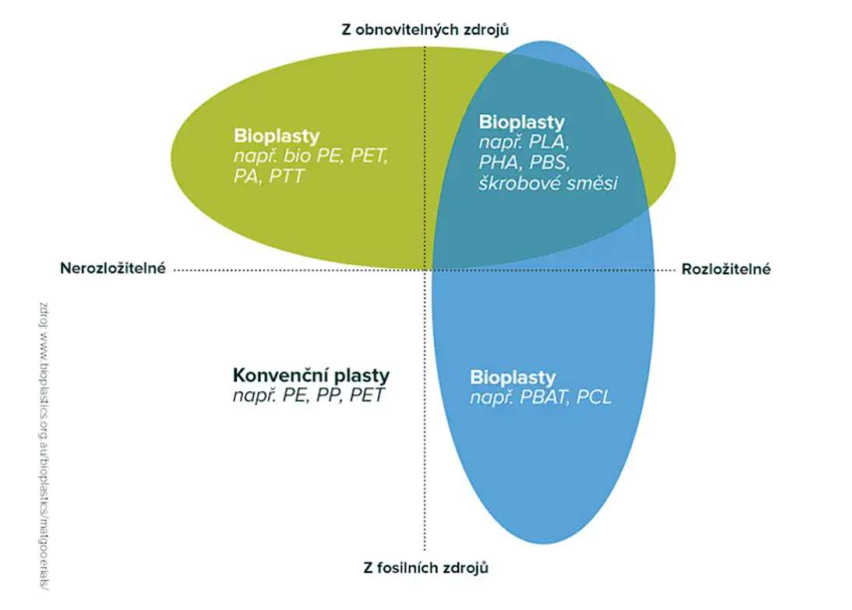

An interesting alternative might seem to be the choice of one of the bioplastics, of which there are currently around 300 types. However, this solution primarily brings additional problems. Even basic terms like "bioplastic" and "biodegradable plastic" are often confused, and this fact alone significantly complicates sorting and the subsequent handling of resulting waste.

Due to the intentional instability of these materials, disposing of them in plastic waste is undesirable, as contamination of sorted plastic with these materials negatively impacts the quality of the recyclate and, consequently, its purchase price. Excluding them at the sorting line is also challenging due to their visual similarity.

Disposing of bioplastics in bio-waste containers is not an optimal solution either. The biodegradability itself and its conditions are often questions that even manufacturers cannot fully answer.

Many attempts at composting bioplastics fail because their decomposition often requires unrealistic conditions in nature, such as temperatures exceeding 60°C. Tests even show that standard composting methods are often insufficient. More energy-intensive processes, which are not commonly used for composting, are frequently required, leading to additional problems and increasing the energy intensity of the process.

Additionally, it fosters the misconception in many people that discarding such packaging in nature is acceptable, which unfortunately is not true. Moreover, composted material (assuming it actually decomposes) can no longer be recycled, and all the resources used in its production are lost, unlike with recycling. Recycling would be feasible if the material were sorted on the same basis, but given the vast number of bioplastic types, this is hard to imagine and would likely discourage sorting efforts.

The path to sustainability for packaging materials should focus less on dead-end “miracle materials” that promise easy solutions without requiring us to change our behavior or actively participate. Instead, it should prioritize using the smallest possible amount of material with the least environmental impact throughout its entire life cycle, considering the protected product and ensuring simple sorting and recycling options.

Most importantly, building sufficient recycling capacities for both paper and plastic is crucial. Currently, most sorted waste is exported outside Europe, causing us to lose valuable raw materials that could be reused.

Advantages of Using Air Cushions:

- Minimal storage requirements

- Minimal transportation demands (low weight)

- Large filled volume with minimal material

- Minimal volume of easily sortable and recyclable waste

- No shape memory (does not retain deformation)

- HDPE recyclable up to 10 times (paper max. 7 times)

Advantages of Using Crumpled Paper:

- Suitable for products with sharp shapes and edges

- Easy marketing approach for an uninformed public